Laimi Bag: Professional Handbag

Manufacturing Partner

Laimi Bag

Factory

Startup Friendly Manufacturer.

From Sketch to Tech Pack to Production.

Low MOQ (Start from 30 pcs) to help you launch your brand.

Why Choose Us?

We are more than just a manufacturer; we are your trusted partner. With our four core advantages, we ensure every idea is perfectly realized.

Strict Quality Control

Following the Higg standard system, we conduct 5 inspection stages from raw materials to finished products, ensuring a qualification rate of over 99%.

Fast Delivery

Standardized production and an efficient supply chain allow for samples in 7-15 days and mass production delivered in 30-45 days.

Small MOQ, Quick Turnaround

Starting from 30-200 pieces, we offer flexible production to adapt to market changes, reducing your inventory and trial costs.

Experienced Team

Our design and pattern-making team of over 20 professionals deeply understands brand needs, providing solutions that are both aesthetic and commercial.

Production Capabilities

Key manufacturing metrics at a glance for procurement teams.

| Metric / Standard | Laimi Bag Factory Data |

|---|---|

| Monthly Capacity | 78,000+ Pieces / Month |

| Minimum Order (MOQ) | 30 - 200 Pieces (Flexible Support) |

| Sample Lead Time | 3 - 7 Days (Fast Turnaround) |

| Bulk Production Time | 30 - 45 Days |

| Quality Standard | AQL 2.5 / 4.0 (100% Full Inspection) |

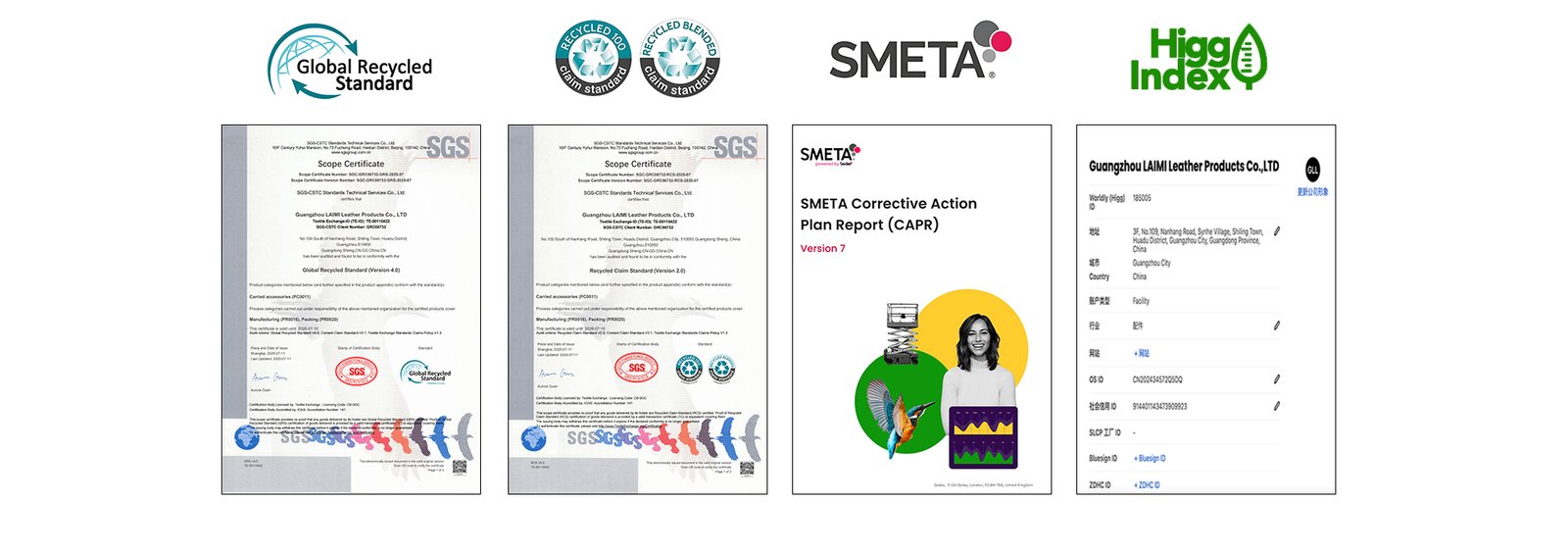

| Certifications | Higg, BSCI, SMETA, GRS |

| Main Markets | North America (40%), Middle East (35%), Europe (25%) |

About Laimi

Laimi is a manufacturing enterprise specializing in mid-to-high-end handbags. With a 5,000 m² standardized workshop and 105 imported sewing machines, we have provided OEM/ODM services to over 100 brands worldwide for the past 10 years, with a monthly output of up to 78,000 bags. Our product line covers genuine leather, PU, canvas, and more, making us a reliable partner in your brand's growth.

GRS

GRC

SEDIX

HIGG

Our OEM/ODM Services

We offer comprehensive handbag manufacturing services, covering every stage from concept to finished product.

Design & Development (ODM)

We offer free design consultation, creating exclusive solutions based on your needs and supporting 2D mockups to quickly turn your ideas into reality.

Made to Order (OEM)

We support manufacturing from your drawings, samples, or provided materials. We accurately replicate your designs, ensuring product consistency and quality.

One-Stop Supply Chain

We integrate high-quality leather, hardware, and accessory resources. All materials are SGS certified, saving you the hassle of procurement.

How We Master the "Small Details" That Others Miss

A factory's true value is revealed in how it solves common, stubborn quality problems. Here are our solutions to major client pain points.

The Pain Point: "Wavy" or "Rippled" Zippers

A client came to us frustrated. Their previous factory's bags had wavy zippers, which not only looked cheap but caused snagging and jamming.

Our Solution: We solve it with a 5-point system, including skilled "even-speed feeding" by operators and precise machine tension calibration.

See Our Full 5-Step Zipper Solution →

The Pain Point: "Cracking" or "Peeling" Edge Paint

New brands often find their bag's edge paint cracks and peels off after just a few months. This is disastrous for brand reputation.

Our Solution: We use high-quality imported edge paint, applying 4-5 layers with manual sanding and polishing between each layer.

See Our Edge Painting Process →

The Pain Point: "Tarnishing" or "Fading" Hardware

A common complaint is that metal buckles lose their shine or rust. This makes a premium bag feel cheap.

Our Solution: We only source from certified hardware suppliers who provide proper electroplating. We require Salt Spray Test reports.

Learn About Our Hardware QC →

The Pain Point: "Wrinkled" Bags After Packing

Brands are frustrated when customers receive bags with permanent creases. This is often a sign of cheap materials.

Our Solution: We use high-resilience leathers and combine this with structural packing (internal paper support) to ensure perfect arrival.

See Our Material & Packing Solution →Case Studies

Our work speaks for itself. Every case is a testament to our exquisite craftsmanship.

Client Factory Audits

We regularly welcome factory audits, demonstrating our standardized processes.

Dubai International Bag Fair

Showcasing our latest designs and craftsmanship in Dubai.

Designer Brand Production

Helping emerging designers turn sketches into reality with successful mass production.

CANTON FAIR

As a regular exhibitor, showcasing our core manufacturing capabilities.

SCOPE Certification

Demonstrating compliance with sustainable production standards.

SMETA Audit

Upholding the highest standards of labor rights, health, and safety.

What Our Clients Say

Our service has earned the recognition of many partner brands.

Working with Laimi is a breeze! Their team is professional and does an excellent job with quality control.

Laimi not only supports small-batch customization but also has a very fast response time. Ideal partner.

Laimi provided us with so much professional advice, from material selection to hardware matching. Thank you!

Frequently Asked Questions

Find answers to your questions here.

What is your Minimum Order Quantity (MOQ)?

Our MOQ is flexible, starting from 30-200 pieces for most styles.

How long does sampling take and what is the cost?

Sampling typically takes 3-7 days. We offer the first sample for free!

What is the lead time for mass production?

Generally 30-45 days. Small orders under 500 pieces can often be completed in 7-30 days.

What material options do you provide?

We offer genuine leather, high-quality PU, microfiber, canvas, and nylon, plus SGS certified hardware.

Start Your Customization Journey

Our consultant will contact you within 24 hours.

Contact Information

+86-19924378865

+86-19924378865

sale08@laimibags.com

No.150 Zhen Xing Road, Shiling Town, Huadu District, Guangzhou